1 Introduction

The wind generators are machines responsible for transforming

the kinetic energy of the wind into mechanical energy by rotating the blades of

a rotor that, connected to a generator, is capable of converting mechanical

energy into electricity. Their increasing use in the global scenario have also

led to the need for constant studies related to their control systems in order

to guarantee the integrity of the tower, wind turbine and mechanical

components, as well as to guarantee good operating performance. Among the

different aspects existing in control systems, such as overcurrent control,

short circuits, overvoltage, and others, there is a concern about the efficient

control of the structure's vibration [1, 2, 3].

The wind tower is an important component of the wind system,

as it is responsible for sustaining the wind turbine. Over time, a notable

factor is the increase in the height of these towers, subjecting the entire

structure and mechanical components to greater vibration effects, thus

demonstrating the importance of introducing an adequate structural vibration

control [4].

Devices such as TMD (Tuned Mass Damper), Controllable Fluid

Dampers, TLD (Tuned Liquid Dampers, among others, can be used in order to

promote structural vibration control. The dampers can also be classified as

passive, active or semi-active, where the main difference is in the use or not

of external power to absorb vibration energy. In a passive system this control

occurs only due to the presence of springs and dampers, or even a pendulum,

while in an active system the control occurs by adding an active element, being

possible to find in the system controllers and actuators, responsible for

calculating the necessary force to control the vibration and apply it to the

structure. A semi-active system, in turn, uses external energy only in the

modification of the stiffness and damping parameters of the device, not on

direct application in the vibration attenuation as in the active control [3, 5].

2 Tuned Mass

Damper (TMD) and its Optimal Parameters

The TMD is characterized by the use of a mass  , a spring of stiffness

, a spring of stiffness  and a damper of

coefficient

and a damper of

coefficient  , where tuning its natural

frequency to the frequency to be controlled, this device is able to control the

vibration of the structure where it was implemented. An alternative geometry

for the TMD is the pendulum, where it is modeled with a hanging mass that sways

in the opposite movement to the excited structure. TMD has great applicability

in tall buildings, bridges, towers and, also, in wind towers, and can be used

as a passive, active or semi-active device. It is usually located at the point

of greatest modal amplitude, in order to attenuate the vibrations related to

the first mode of vibration [3, 5].

, where tuning its natural

frequency to the frequency to be controlled, this device is able to control the

vibration of the structure where it was implemented. An alternative geometry

for the TMD is the pendulum, where it is modeled with a hanging mass that sways

in the opposite movement to the excited structure. TMD has great applicability

in tall buildings, bridges, towers and, also, in wind towers, and can be used

as a passive, active or semi-active device. It is usually located at the point

of greatest modal amplitude, in order to attenuate the vibrations related to

the first mode of vibration [3, 5].

The

parameters of stiffness, mass and damping of a TMD can be calculated from the

dynamic equilibrium equations of the Structure-TMD system. It is commonly used

to reduce the degrees of freedom of the structure, simplifying the system and

facilitating the calculation procedures. It is also important to know the

frequency at which the TMD should act and the structure's damping. TMD

parameters must be dimensioned in order to obtain the best possible vibration

control results, that is, minimizing the amplitude of movement of the structure.

In the response of a 2 degree of freedom system, for example, in the frequency

domain graph, there are two points where all curves pass, regardless of the

value of the TMD damping factor,  . The so-called ideal curve

is one where these two points are equivalent to the peaks of the curve (that

is, zero slope), and whose height of both points tend to the same value. Then

applying these conditions, the so-called optimal parameters of the TMD are

obtained [6, 7].

. The so-called ideal curve

is one where these two points are equivalent to the peaks of the curve (that

is, zero slope), and whose height of both points tend to the same value. Then

applying these conditions, the so-called optimal parameters of the TMD are

obtained [6, 7].

For

the case of a mass subject to free vibration where a TMD is introduced, the

result is a system of 2 degrees of freedom as shown in Figure 1, governed by

the dynamic equilibrium equations shown in Equation (1), where the parameters

with index  represent TMD, and with

index

represent TMD, and with

index  represent the main mass.

represent the main mass.

Figure 1: Theoretical model of 2 DOF representing a structure with

damping and with a TMD installed, subject to free vibration [adapted].

Source:

Paredes, M. M. [6].

For this case, after application of the previously mentioned

conditions and performing the proper mathematical calculations, it’s possible

to get the following equations of optimal parameters  and

and  of TMD shown in Equations

(2) and (3), where

of TMD shown in Equations

(2) and (3), where  is the ratio of

frequencies of the TMD and mass (

is the ratio of

frequencies of the TMD and mass ( ),

),  and

and  are the factor damping of

TMD and mass respectively, and

are the factor damping of

TMD and mass respectively, and  is the mass ratio (𝜇 =

is the mass ratio (𝜇 =  ) [6].

) [6].

As mentioned, these equations correspond to the case of a

mass subject to free vibration, but will vary depending on the conditions under

which the system is subject, such as harmonic or random actions.

This work aims to propose a TMD to act on the first natural

frequency of a wind tower subject to free vibration, dimensioning its optimal

parameters and evaluating its influence on the system.

3 Methodology

3.1 Dynamic

Analysis of Wind Tower

For

this study, a small wind tower present on the Campus of the Polytechnic

Institute of Bragança (IPB), with peak power equal to 1.4 kWp, was used as the

object of study, as shown in Figure 2.

(a)

(b)

Figure 2: Horizontal-axis wind tower of the IPB Campus - (a) Wind

generator and part of the tower, (b) bottom of the tower.

Source:

Author.

The tower was modeled numerically using the finite element

method in the ANSYS software. Then, from the dynamic analysis it was possible

to obtain its natural frequencies and modes of vibration. For this purpose,

simulations were made considering the upper end of the structure as being free

and its base fixed, since this configuration is considered in the bibliography

as a good initial approximation of a real structure base [9].

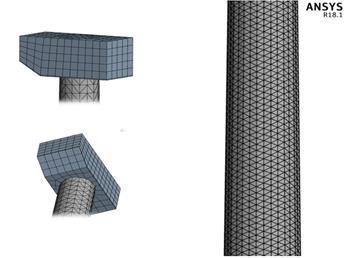

The structure was initially designed in the Autodesk Inventor

software, not taking into account the ladder and structural defects, and the

introduction of the wind turbine on the tower was made in a simplified way,

where this was represented by a massive box fitted on the top of the structure,

having weight equivalent to the total weight of the rotor.

Simplifications of nacelle consist of a satisfactory

simulation practice, which is also used in other works [8, 9, 10,

11, 12].

The wind towers are subjected to different dynamic stresses due to, for

example, the rotor rotation, the action of the wind, and the blade pass through

the tower. However, in this paper, these dynamic effects will not be included,

since the focus here is on observing the natural frequencies of the structure,

analyzing the natural vibration of the tower when subjected only to free

vibration.

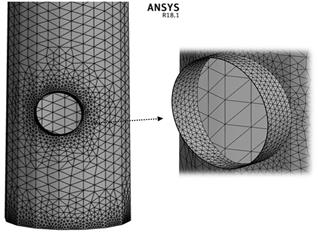

The mesh was then created in the structure using the ANSYS

software, which can be seen in Figure 3. In this step, the convergence of the

results in relation to the first natural frequency of the system was

considered, where in Figure 4 it is possible to see the amount of elements

generated, as well as the first natural frequency equivalent to 1.56 Hz.

(a)

(b)

Figure 3: Meshes in - (a) proximity

to the hole and base, (b) tower and upper part.

Source: Author.

Figure 4: Mesh convergence.

Source: Author.

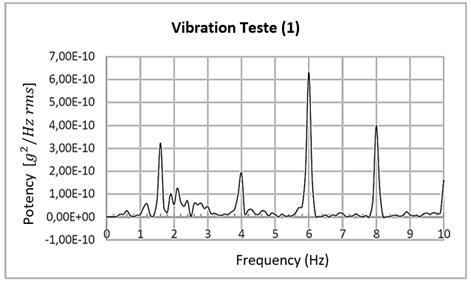

As a parameter for analyzing the frequencies obtained

numerically, the results obtained experimentally by Dias, L. [13] will be considered. In the

test, two accelerometers were used at a height of 1.41 m in two different positions

(x and y). The tower was excited using a PCB 086b20 impact hammer, and the

first average frequencies obtained can be seen in Table 1. For this test,

intermediate vibrations were not taken into account, such as vibrations in the

wind turbine, and the frequency spectrum obtained in the test can be seen in

Figure 5.

Table 1: Frequencies obtained experimentally.

|

Frequencies (Hz)

|

|

First

mode of vibration

|

1.61

|

|

Second

mode of vibration

|

5.99

|

Source: Dias, L. [13].

Figure 5: Spectrum of frequencies obtained

experimentally. [adapted].

Source: Dias, L. [13].

3.2 Proposal of

a TMD for the structure

Tuning the TMD means choosing the appropriate mass, stiffness

and damping parameters for a given actuation frequency, so that the movement of

the main structure be minimized. Therefore, first the structure is reduced in

an equivalent mass-spring system of 1 DOF, where its structural parameters are

replaced by its modal (or generalized) parameters that correspond to the mode

of vibration in which the TMD will act. Figure 6 shows schematically this

system of 1 DOF, representing the first mode of flexion of the structure, where

and

and  correspond to the modal

stiffness and mass. The modal mass is obtained from ANSYS itself, and with

that, the modal stiffness can be calculated, since the values of

correspond to the modal

stiffness and mass. The modal mass is obtained from ANSYS itself, and with

that, the modal stiffness can be calculated, since the values of  and natural frequency

and natural frequency  are known. Considering

that steel towers have, in particular, a lower level of structural damping [14, 15], it was considered for

this first approach that the structural damping is approximately zero. In

addition, for cases where this value is reduced (

are known. Considering

that steel towers have, in particular, a lower level of structural damping [14, 15], it was considered for

this first approach that the structural damping is approximately zero. In

addition, for cases where this value is reduced ( ), the design of the TMD

can be performed considering the damping of the structure as zero [7].

), the design of the TMD

can be performed considering the damping of the structure as zero [7].

(a) (b)

Figure 6: (a) Flexion mode (b)

simplified to a modal mass-spring system.

When

introducing the mass-spring-damper TMD into the structure, the system then

changes from 1 DOF to 2 DOF, as shown in Figure 7, where  ,

,  , and

, and  correspond to the

stiffness, damping coefficient and mass of the TMD, respectively, and the

dynamic equilibrium equations of this system can be seen in Equation (4). These

parameters are then dimensioned from the equations of optimal parameters, as

shown in Equations (2) and (3), where adapting them to the system in Figure 7,

they become as follows, as shown in Equations (5) and (6).

correspond to the

stiffness, damping coefficient and mass of the TMD, respectively, and the

dynamic equilibrium equations of this system can be seen in Equation (4). These

parameters are then dimensioned from the equations of optimal parameters, as

shown in Equations (2) and (3), where adapting them to the system in Figure 7,

they become as follows, as shown in Equations (5) and (6).

Figure 7: Mass-spring system with

coupled TMD.

The mass of the TMD  should be chosen

initially, where it is suggested that its value be about 0.5% to 1% of the

total mass of the structure, and in towers of larger size it is also observed

the use of values around 3% [10, 16]. The total mass of the

structure can also be obtained using ANSYS. From the pre-determination of

should be chosen

initially, where it is suggested that its value be about 0.5% to 1% of the

total mass of the structure, and in towers of larger size it is also observed

the use of values around 3% [10, 16]. The total mass of the

structure can also be obtained using ANSYS. From the pre-determination of  and the knowledge of the

modal mass

and the knowledge of the

modal mass  , it is then possible to

find the mass ratio

, it is then possible to

find the mass ratio  , and calculate

, and calculate  and

and  , from where it will be

possible to obtain the stiffness and damping parameters of TMD, as well as its

frequency

, from where it will be

possible to obtain the stiffness and damping parameters of TMD, as well as its

frequency  .

.

After obtaining the TMD’s parameters, the system response is

simulated using the MATLAB software, where an algorithm was developed based on

the previous equations. The tool used to solve the system of differential

equations was ODE45 through the application of the fourth-order Runge-Kutta

Method. The FFT (Fast Fourier Transform) function was also used to obtain the

system's response in the frequency domain.

4 Results and

Discussion

4.1

Dynamic Analysis

From the dynamic analysis performed in ANSYS it was possible

to obtain the natural frequencies and modes of vibration of the structure. It

was observed that for each pair of frequencies the values were very close. The

first two pairs of frequencies obtained numerically are shown in Table 2.

Table 2: Natural frequencies obtained numerically.

|

Frequencies (Hz)

|

|

First

mode of vibration

|

1.56

|

|

Second

mode of vibration

|

1.59

|

|

Third

mode of vibration

|

6.79

|

|

Fourth

mode of vibration

|

6.89

|

Source: Author.

It was

also possible to observe that for each pair of frequencies the modes of

vibration are similar, acting however in opposite directions. Figure 7 shows

the first and second modes of vibration of the structure, corresponding to

flexion modes, where what differentiates them is the direction of action, one

in the X direction and the other in the Z direction. Since the first modes of

vibration are the most important and likely to occur, then the other modes will

not be placed here.

(a) (b)

Figure 7: (a) 1st and (b) 2nd mode of

vibration.

Thus, given the similarity to each pair of frequencies, the

average of these pairs will now be considered, that is, the first frequency

corresponds to the average of the first pair of similar frequencies, and the

second frequency to the average of the second pair of similar frequencies.

4.2

Comparison of Numerical and Experimental Results

From the values of frequency obtained

experimentally, presented in Table 1, and the values of frequency obtained

numerically (considering the average of the pairs of frequency), it is possible

to observe a small error related to the first natural frequency, equivalent to

1.86%, and a 14.19% error related to the second frequency, as shown in Table 3.

Table 3: Experimental and numerical

frequency results and respective errors.

|

Natural Frequency

|

Experimental

|

Numerical

|

Error (%)

|

|

First

mode of vibration (Hz)

|

1.61

|

1.58

|

1.86 %

|

|

Second

mode of vibration (Hz)

|

5.99

|

6.84

|

14.19 %

|

Source: Author.

Then, considering that the first frequency was the best

observed numerically and experimentally, and because it is considered the main

one it was then considered as a parameter of TMD tuning. Therefore, TMD will

act when this frequency is reached, vibrating out of phase in relation to the

movement of the structure.

Some factors may have contributed to

the reported differences such as, for example, the simplification of the

numerical model of the tower, where the ladder present in the structure,

structural defects, and the real shape of the wind turbine were not considered.

The wind turbine was simplified as a slightly decentralized solid box at the

top of the tower, aiming to simulate the effect of the rotor’s center of

gravity on the response of the structure, but being an approximation since the

real value is not known.

Another reason for such differences

may have been due to the experimental test, where vibrations from the wind

turbine may have generated interference in the results. The test performed was

an environmental vibration test, that is, the response of the structure was

obtained being subject to its working and operating conditions. Environmental

vibration tests like this provide large amounts of data that need to be handled

carefully, as the captured signal receives contribution from various

frequencies, such as wind, rotor and blade rotation, and also from the

generator. Therefore, being this type of signal considered white noise, the

natural frequencies of the structure can be recognized through the

identification of frequencies with higher energy content. Therefore, a small

flaw in this identification can also be considered as the cause of the

difference in the results. In addition, the position of the sensors may have

been another cause of the observed differences, where it is suggested that they

be used at different points of the structure for a more satisfactory test.

4.3 Optimal

TMD’s parameters and response of the structure

Initially, the mass of the TMD was considered to be 1% of the

total mass of the structure (equivalent to approximately 752.37 kg), which

corresponds to  = 7.52 kg. The modal mass

referred to the first mode of vibration (

= 7.52 kg. The modal mass

referred to the first mode of vibration ( =1.58 Hz, equivalent to

=1.58 Hz, equivalent to  = 9.93 rad/s) is obtained

from numerical analysis, and corresponds to

= 9.93 rad/s) is obtained

from numerical analysis, and corresponds to  = 353.28 kg. With this,

the modal stiffness is

= 353.28 kg. With this,

the modal stiffness is

The mass ratio  is equivalent to

is equivalent to

With the value of  , the frequency value of

TMD is found, in order to obey the optimal ratio of frequencies

, the frequency value of

TMD is found, in order to obey the optimal ratio of frequencies  . Therefore,

. Therefore,

From Equation (6) it is also possible to find the optimal

value of the damping factor for TMD, from where the damping coefficient  will be obtained.

will be obtained.

With these values of  and

and  , the stiffness required

for TMD will be

, the stiffness required

for TMD will be

Table 4 presents, briefly, the values of the parameters

obtained for the TMD.

Table 4: TMD’s parameters for

vibration control of the first mode of vibration of the structure.

|

Parameter

|

Value

|

Unit

|

|

Mass

|

7.52

|

kg

|

|

Stiffness

|

711.65

|

N/m

|

|

Damping

|

20.48

|

N.s/m

|

Once the optimal TMD parameters were determined, it was then

possible to obtain the system response graphs shown in Figure 8, through

MATLAB.

Figure 8: Response of the spring-mass system with and without coupled

TMD, in the time and frequency domain:  =7.52kg,

=7.52kg,  =711.65 N/m,

=711.65 N/m,  =20.48 N.s/m.

=20.48 N.s/m.

As can be observed, the presence of TMD resulted in the rapid

attenuation of the tower vibration. The two new frequencies obtained for the

present case were  =1.56 Hz and

=1.56 Hz and  =1.57 Hz as can be seen in

the frequency domain response graph. In this same graph it is possible to

visualize the detachable difference that exists in the amplitude for the

frequencies of the system without TMD and with TMD, where these amplitudes are related

to the amount of energy in the vibration movement for the simulation time

considered. Therefore, the system response without TMD presents the highest

peak because throughout the simulation time its vibratory energy is constant,

while the system response with TMD presents much smaller amplitudes, for the

mass of the TMD and for the mass of the tower, because during the simulation

time both masses present a decrease of their vibration energy.

=1.57 Hz as can be seen in

the frequency domain response graph. In this same graph it is possible to

visualize the detachable difference that exists in the amplitude for the

frequencies of the system without TMD and with TMD, where these amplitudes are related

to the amount of energy in the vibration movement for the simulation time

considered. Therefore, the system response without TMD presents the highest

peak because throughout the simulation time its vibratory energy is constant,

while the system response with TMD presents much smaller amplitudes, for the

mass of the TMD and for the mass of the tower, because during the simulation

time both masses present a decrease of their vibration energy.

Increasing the mass  , it was observed that the

vibration attenuation occurs faster and that the amplitude of the displacement

suffered by the TMD becomes smaller. In addition, from the frequency domain

graph it was noticed that the peaks of the curve of the Tower-TMD system become

smaller and closer to each other in height [17]. This can be observed in

Figure 9, where

, it was observed that the

vibration attenuation occurs faster and that the amplitude of the displacement

suffered by the TMD becomes smaller. In addition, from the frequency domain

graph it was noticed that the peaks of the curve of the Tower-TMD system become

smaller and closer to each other in height [17]. This can be observed in

Figure 9, where  was increased by 10% of

the total mass of the structure and the other parameters were updated within

the optimal conditions. However, although the use of a larger mass is

apparently a good choice, it is advisable to evaluate the design limitations such

as, for example, the space available in the tower for TMD installation.

was increased by 10% of

the total mass of the structure and the other parameters were updated within

the optimal conditions. However, although the use of a larger mass is

apparently a good choice, it is advisable to evaluate the design limitations such

as, for example, the space available in the tower for TMD installation.

Figure 9: Response of the spring-mass system with and without coupled

TMD, to  equal to 10% of the total

mass of the structure:

equal to 10% of the total

mass of the structure: =75.24 kg,

=75.24 kg,  =5108.62 N/m,

=5108.62 N/m,  =520.78 N.s/m.

=520.78 N.s/m.

4.4 Influence of

the change of TMD’s parameters on the structure response, without the correct

adequacy to optimal conditions

Now, through the variation of TMD parameters so that they

disperse from their optimal values, it will be possible to observe how the

vibration attenuation of the structure occurs and, consequently, to evaluate

what is the need to use the equations of optimal parameters correctly.

First, the mass  was varied, where the

other parameters

was varied, where the

other parameters  and

and  were kept constant, that

is, they were not updated according to the equations of optimal parameters.

Figure 10 shows the answer for the case of

were kept constant, that

is, they were not updated according to the equations of optimal parameters.

Figure 10 shows the answer for the case of  =4.51 kg, that is, reduced

by 40% of its initial value. Figure 11 shows the answer for the case of

=4.51 kg, that is, reduced

by 40% of its initial value. Figure 11 shows the answer for the case of  =10.53 kg, that is,

increased by 40%.

=10.53 kg, that is,

increased by 40%.

Figure 10: Response of the spring mass system with and without coupled

TMD, to  reduced by 40% (

reduced by 40% ( =4.51 kg), and

=4.51 kg), and  =711.65 N/m,

=711.65 N/m,  =20.48 N.s/m.

=20.48 N.s/m.

Source: Author.

Figure 11: Response of the spring-mass system with and without coupled

TMD, to m_t increased by 40% ( =10.53 kg), and

=10.53 kg), and  =711.65 N/m,

=711.65 N/m,  =20.48 N.s/m.

=20.48 N.s/m.

In both graphs, less efficient results in vibration

attenuation are observed, mainly with  reduction. In cases where

the parameters are even more distant from their optimal values, it is possible

to observe situations where attenuation does not occur, as shown in Figure 12.

reduction. In cases where

the parameters are even more distant from their optimal values, it is possible

to observe situations where attenuation does not occur, as shown in Figure 12.

Figure 12: Response of the mass-spring system with and without coupled

TMD, to  =9 kg,

=9 kg,  =3 N/m and

=3 N/m and  =20040 N.s/m.

=20040 N.s/m.

It

is also valid to point out that, in cases where the TMD is designed to act when

a certain external force is applied, if its parameters are not carefully

implemented, it will be possible to observe that there may be an increase in

the dynamic amplitude of the tower.

Similarly, the damping  was also varied, where the

other parameters

was also varied, where the

other parameters  and

and  were kept constant, that

is, they were not updated according to the equations of optimal parameters.

Figure 13 shows the answer for the case of

were kept constant, that

is, they were not updated according to the equations of optimal parameters.

Figure 13 shows the answer for the case of  = 4.08 N.s/m, that is,

reduced by 80% of its initial value. Figure 14 shows the answer for the case of

= 4.08 N.s/m, that is,

reduced by 80% of its initial value. Figure 14 shows the answer for the case of

= 36.80 N.s/m, that is,

increased by 80%.

= 36.80 N.s/m, that is,

increased by 80%.

Figure 13: Response of the spring-mass system with and without coupled

TMD, to  reduced by 80% (

reduced by 80% ( =4.08 N.s/m), and

=4.08 N.s/m), and  =711.65 N/m,

=711.65 N/m,  =7.52 kg.

=7.52 kg.

Figure 14: Response of the spring-mass system with and without coupled

TMD, to  increased by 80% (

increased by 80% ( =36.80 N.s/m), and

=36.80 N.s/m), and  =711.65 N/m,

=711.65 N/m,  =7.52 kg.

=7.52 kg.

With

the reduction of the damping coefficient, it is observed that the displacement

of the TMD starts to present greater amplitudes, and the vibration of the tower

remains for a longer time. It is also possible to notice the inconsistency in

the vibration attenuation, where in some periods there is a slight increase in

the vibration where it immediately reduces again. On the other hand, with the increase

of the damping coefficient, the TMD starts to present smaller displacements,

but the time of vibration attenuation of the tower continues to be greater than

the time observed in the responses obtained through the optimal parameters

(Figures 8 and 9).

In all cases, it is notable that the responses tend to

be more efficient as the TMD’s parameters converge to their values considered

optimal.

As a last consideration, it is worth noting that, since free

vibration has been treated here, the amplitude of the masses displacements

observed in the responses is dependent on the initial displacement of the tower

adopted in the simulations (this is a case of a Possible and Indeterminate

System). However, in a constructive TMD project, it is important that an experimental

study of the tower vibration amplitudes be carried out, thus obtaining adequate

initial conditions for the simulation. Depending on these conditions, the

diameter of the tower where the TMD would be installed (upper internal

diameter) must be large enough to allow the displacement of  and to accommodate the

other elements of the system, such as spring, damper and guides. However,

regardless of such imposed conditions, the application of the optimal

parameters of the TMD will imply an optimized attenuation of the tower

vibration.

and to accommodate the

other elements of the system, such as spring, damper and guides. However,

regardless of such imposed conditions, the application of the optimal

parameters of the TMD will imply an optimized attenuation of the tower

vibration.

The construction and implementation of the TMD would consist

of another stage of the study, where it would be necessary to gather the design

restrictions, from the dimensions to the limited commercial availability of

elements (as is the case of the dampers in relation to their damping factor).

In this work, constructive details are not within the objective. However, Figure

15 schematically shows a possible arrangement of the elements in the system,

where the ends would be fixed to the internal walls of the tower (the TMD could

also, alternatively, be implemented inside the nacelle, or even outside the

tower, which possibly require a different arrangement of the elements).

However, this is only a possible implementation, as the elements (spring and

damper) could also be placed both on the same side, as shown by LIMA, D. M. [10]. He proposes a constructive

model, where guides and rails are implemented for the translation of the mass

in the correct direction. It is also worth mentioning that TMD should act in two

different directions (X and Z) regarding the 1st and 2nd modes of vibration of

the tower (see Figure 7), therefore two complete TMDs can be applied to the

system (one for each direction mentioned), or a special arrangement for just

one TMD must be developed taking in consideration acting in two direction.

Figure 15: Scheme showing possible arrangement of system elements.

5. Conclusions

Through the dynamic analysis of a wind tower, performed

numerically, it was possible to extract information of frequency and modes of

vibration of the tower, where when comparing them with experimental results,

the first frequency was the one that presented the most satisfactory result,

what made this frequency chosen for TMD tuning. These differences may have

resulted from simplifications of the numerical model, or from possible errors

in the identification of natural frequencies through experimental analysis,

since in an environmental vibration test the structure receives the

contribution of different excitation frequencies, and then, the natural

frequencies must be carefully identified through the energy content of the

signals obtained.

In the proposal of a TMD for the structure it was possible to

verify that the use of the equations of optimal parameters generated

satisfactory results, providing the best result in the vibration attenuation of

the tower. This statement could be confirmed by observing that the results were

more efficient when the TMD’s parameters converged to their values considered optimal.

For the simulated case, of free vibration, the system is not

being continuously excited by external force and, therefore, in the simulation

it is only observed how fast or slow the vibration attenuation occurs due to

the variations in the parameters. However, in case of simulations with forced

systems, the inappropriate use of TMD parameters can lead to amplification of

the system’s vibration, causing the resonance effect, and that would be a

proposal for future work.

References

[1] RITCHIE, H; ROSER, Ma. - Energy

Production & Changing Energy Sources: Our World in Data, 2019. Available

in: <URL: https://ourworldindata.org/energy-production-and-changing-energy-sources>. [Consult.

2019-11-05].

[2] MANWELL, J. F.; MCGOWAN, J. G.; ROGERS, A. L. – Wind Energy

Explained: Theory, Design and Application. 2ª Ed. London: WILEY, 2009.

[3]

RAHMAN, M.;

Et. al. – Performance enhancement of wind turbine systems with vibration control:

A review – Renewable and Sustainable Energy Reviews – Malaya (2015-06-19) –

51:43-54. http://dx.doi.org/10.1016/j.rser.2015.05.078.

[4] GASCH, R.; TWELE, J. – Wind Power Plants: Fundamentals,

Design, Construction and Operation. 1ª Ed. Berlin: Taylor&Francis Ltd,

2002.

[5] COLHERINHAS, G. B. ; Et al. – Wind Tower Vibration Controlled by a

Pendulum TMD using Genetic Optimization: Beam Modelling – Procedia Engineering

– Brasília (2017) - 199: 1623-1628. DOI:10.1016/j.proeng.2017.09.080.

[6]PAREDES, M. M. – Utilização de

Amortecedores de Massas Sintonizadas no Controlo de Vibrações em Estruturas.

Dissertação de Mestrado em Engenharia Civil – Faculdade de Engenharia da

Universidade do Porto (FEUP), 2008. Available in: <URL:https://repositorio-aberto.up.pt/bitstream/10216/59514/1/000129395.pdf>. [Consult. 2020-03-11].

[7]

MOUTINHO, C. M. R. –

Controlo Passivo e Activo de Vibrações em Pontes de Peões. Dissertação de

Mestrado em Estruturas de Engenharia Civil – Faculdade de Engenharia do Porto

(FEUP), 1998. Available

in: <URL: https://repositorio-aberto.up.pt/bitstream/10216/12999/2/Texto%20integral.pdf>. [Consult. 2020-03-06].

[8]

SIRQUEIRA, A. S. –

Comportamento Estrutural de Torres de Aço para Suporte de Turbinas Eólicas.

Dissertação de Mestrado em Engenharia Civil – Universidade do Estado do Rio de

Janeiro (UERJ), 2008. Available in: <URL:http://www.labbas.eng.uerj.br/pgeciv/nova/files/dissertacoes/22.pdf>. [Consult. 2020-03-11]

[9]

OLIVEIRA, L. F. M. P.

– Análise do Comportamento Dinâmico de Torres de Geradores Eólicos. Dissertação

de Mestrado em Engenharia Civil, Especialização em Estruturas – Faculdade de

Engenharia do Porto (FEUP), 2012. Available in: <URL:https://repositorio-aberto.up.pt/bitstream/10216/68265/1/000154677.pdf>. [Consult. 2020-03-06]

[10] LIMA, D. M. – Análise

da estabilidade elástica, análise dinâmica e controle de vibração em torres

tubulares de aço para aerogeradores de eixo horizontal. Tese de Doutorado em

Engenharia Civil – Universidade Federal de Pernambuco (UFPE), 2018. Available in:

<URL: https://attena.ufpe.br/bitstream/123456789/31108/1/TESE%20Douglas%20Mateus%20de%20Lima.pdf>. [Consult. 2021-01-15]

[11] DAGLI, B. Y. ; TUSKAN, Y. ; GOKKUS, U. –

Evaluation of Offshore Wind Turbine Tower Dynamics with Numerical Analysis –

Advances in Civil Engineering - Turkey (2018) – Article ID 3054851. https://doi.org/10.1155/2018/3054851.

[12] MURTAGH, P. J. ; BASU, B. ; BRODERICK, B. M. –

Simple models for natural frequencies and mode shapes of towers supporting

utilities – Computers & Structures – Ireland (2004) – 82: 1745-1750. https://doi.org/10.1016/j.compstruc.2004.04.005.

[13]

DIAS, L. D. –

Proposta de um Modelo de Cálculo para o Dimensionamento de uma Torre Eólica a

partir da Análise Dinâmica e Estática. Dissertação de Mestrado em Engenharia da

Construção – Instituto Politécnico de Bragança (IPB), 2018. Available in: <URL:https://bibliotecadigital.ipb.pt/bitstream/10198/18298/1/pauta-relatorio-11.pdf>. [Consult. 2020-03-02]

[14] LIMA, D. M. ; LÓPEZ-YÁNEZ, P. A. ; PEREIRA, M.

A. – Vibration control device for steel tubular towers of Horizontal Axis

Wind Turbines – Lat. Am. J. solidus struct – Rio de Janeiro, Brasil (2019) – 6,

n. 16. https://doi.org/10.1590/1679-78255436.

[15] ASSOCIAÇÃO BRASILEIRA

DE NORMAS TÉCNICAS. NBR 6123:1998, versão corrigida 2:2013. Forças devidas ao

vento em edificações. Rio de Janeiro: ABNT, 2013.

[16] HOUSNER, G. W.; Et al. –

Structural Control: Past, Present, and Future – Journal of Engineering

Mechanics – Reston (1997, September) – 123(9):897-971.https://doi.org/10.1061/(ASCE)0733-9399(1997)123:9(897).

[17] LU, Z. ;

WANG, D. ; LI, P. – Comparison Study of Vibration Control Effects between

Suspended Tuned Mass Damper and Particle Damper – Shock and Vibration – China

(2014) – Article ID 903780. http://dx.doi.org/10.1155/2014/903780.

https://orcid.org/0000-0002-7363-4229

https://orcid.org/0000-0001-6994-0218

https://orcid.org/0000-0001-5640-0714

https://orcid.org/0000-0002-9510-144X