A Comparative

Study of Forecasting Methods in the

Context of Digital Twins

1Escola

Politécnica de Pernambuco, Universidade de Pernambuco, Recife, Brasil. E-mail: jcsm@ecomp.poli.br

2Centro de Informática, Universidade

Federal de Pernambuco, Recife, Brasil.

DOI: 10.25286/repa.v9i1.2771

Esta obra apresenta Licença Creative Commons Atribuição-Não Comercial

4.0 Internacional.

Como citar este

artigo pela NBR 6023/2018: João Souto Maior; Byron Leite Dantas Bezerra; Luciano

Leal; Celso A. M. Lopes Junior; Cleber Zanchettin. A Comparative Study of

Forecasting Methods in the Context of Digital Twins. Revista de Engenharia e

Pesquisa Aplicada, v.9, n. 1, p. 28-40, 2024. DOI: 10.25286/repa.v9i1.2771

ABSTRACT

This paper

describes and compares different forecasting techniques used to build a

real-world Industry 4.0 application using concepts of Digital Twins. For this

experiment, real data collected from a temperature sensor during the initial

stages of a manufacturing process is used. This raw data from the sensors is

preprocessed using state-of-the-art time series techniques for gap removal,

normalization, and interpolation. The processed data are then used as input for

the selected forecasting techniques for training, forecasting, and tests.

Finally, the rates of the different techniques are compared using accuracy

measures to determine the most accurate technique to be used in the application

to support its forecasting use cases. This paper also explores different areas

that can be used as topics for future work.

KEY-WORDS:

Digital

Twins; Sensors; Time Series; Forecasting.

1 INTRODUCTION

The concept of digital

twins is indeed relatively new in its popularized form [1], but its underlying

principles have been applied in various industries for many years. Michael

Grieves is often credited with introducing the term digital twins in 2002 during

a conference in the context of product lifecycle management (PLM). However, it

is essential to note that the idea of creating digital representations of

physical objects or systems happened before this term was coined.

Historically, there has

been little consensus on the exact definition of digital twins, or the

terminology used to describe them. This lack of agreement stems from the

multidisciplinary nature of digital twins, which can be applied to various of

fields, from manufacturing to healthcare, and beyond [2], represented in Figure 1.

Figure 1 – Digital Twins applications

Source: [2]

In 2020, the Digital Twin

Consortium was established by member companies to address this problem [3]. The consortium primarily

focuses is on standardizing technology and terminology related to digital twins

to promote their wider adoption across industries. This effort reflects the

growing recognition of the potential benefits that digital twins can offer in

terms of improving product design, manufacturing processes, asset management,

and overall system performance.

Digital twins create

virtual representations of physical objects, systems, or processes to monitor,

simulate, and optimize their behavior and performance. These virtual

representations are continuously updated with real-time data, allowing for

better decision-making, predictive maintenance, and enhanced domain efficiency.

Within the scope of

Industry 4.0 and the amount of data provided by the Internet of Things (IoT),

it is possible to compute a digital replica of a physical asset. This so-called

Digital Twin replica ideally represents all the behaviors and functioning of

the physical twin. The high-fidelity Digital Twin model of physical assets can

produce system data close to physical reality, which offers extraordinary

opportunities for forecasting, simulation, and diagnosis of asset failures.

Moreover, in forecasting Digital Twins can be used to optimize the energy

consumption of assets, reducing operational costs and environmental impact.

They help in fine-tuning parameters for optimal performance while minimizing

energy usage.

In this context, this work

investigates different forecasting techniques used to build a real-world

Industry 4.0 application using concepts of Digital Twins, comparing such

methods with real data collected from a temperature sensor during the initial

stages of a manufacturing process. As described in Figure 2, sensor data is

collected from an industry and its data is consolidated into an IoT Hub to be

used as inputs for the different digital twin’s models that are generated from

the selected assets of the chosen industry. Finally, this data is presented to

the end users as dashboards, graphs, and reports informing them of the real and

predicted condition of the equipment.

Figure 2 – Digital Twins applications

diagram

Source: Author

The paper is organized as

follows. Section 2 outlines the related work on time series forecasting.

Section 3 discusses the materials and methods of this article with the results

of each selected forecasting method. Section 4 presents a comparison of the

results of the selected methods. Section 5 offers the study’s conclusion and list

different areas that can be used for future works.

2 BACKGROUND AND RELATED WORKS

2.1 TIME SERIES PREPROCESSING

Univariate time series

data, characterized by a sequence of observations recorded at successive time

points, find applications in diverse domains, including finance, healthcare, meteorology,

and industrial processes. Before employing advanced analysis and

forecasting methods, it is crucial to effectively preprocess the data to

enhance its quality, remove noise, and ensure reliable results [4], [5], [6].

Outliers, extreme values

that deviate significantly from the general trend of the data, can distort

statistical analyses and modeling efforts. Techniques such as z-score-based [7] methods can help identify

and remove these outliers, ensuring the accuracy of subsequent studies.

IoT-generated time series

data can exhibit outliers due to various factors including sensor malfunctions,

transient disturbances, or even cyber-attacks. Identifying these outliers is

crucial, as they can distort the temporal patterns important to accurate

predictions in IoT systems.

The mean absolute deviation

(MAD) which its formula is described in equation 1, emerges as a powerful

approach to detecting outliers within time series data [7]. Given IoT data’s dynamic

and evolution, the MAD method accounts for the absolute deviations of

individual data points from the median of the entire time series. This

adaptability is particularly valuable in IoT scenarios, where outliers might

emerge from previously unseen events or irregularities.

(1)

(1)

The values identified as

outliers were removed from the time series and the gaps created after the

removal were filled using linear interpolation. Missing values are expected in

time series data and can arise for various reasons. Imputing missing values is

essential to ensure a continuous and complete time series for analysis. Linear

interpolation is widely used to estimate missing values based on neighboring observations

and is a widely used method [8].

Time series data often vary

in scale and magnitude, leading to biased analyses and misleading

interpretations. Normalization, whose formula is described in equation 2,

ensures that all features are brought to a standard scale, eliminating the

dominance of high-scale variables in analyses like clustering, classification,

and regression. In the formula, min and max values refer to the normalization

of the variable x, and y is the normalized value.

(2)

(2)

It is essential to verify

the time series stationarity. The Augmented Dickey-Fuller (ADF) [9] test is a widely used

statistical test to determine if a time series is stationary [10], meaning that its

statistical attributes remain unchanged over the time.

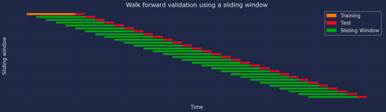

Walk-forward

validation using a sliding window [11], represented in Figure 3 and known as

rolling validation or moving window validation, is a time series

cross-validation technique used to assess the performance of time series

forecasting models. Unlike traditional cross-validation, where data is randomly

shuffled, maintaining the temporal order of the data, which is crucial for time

series analysis, Walk-forward validation simulates the real-world scenario of

making sequential predictions as new data becomes available over time.

Figure 3 – Walk Forward validation with

a sliding window.

Source: Author.

Walk-forward validation

also considers the model to be fitted every time the window is moved forward

along the time series. Still, since the collected data from the sensor is a stationary

time-series, it is not necessary to re-fit the model. This represents less

computational requirements during the execution of tests and during the usage

of the model in real-time with new data from the sensors.

A primary advantage of this

method is that more data is used to train and test the model without having to

use a validation set and without the risk of overfitting [12].

2.2 FORECASTING METHODS

2.2.1 Baseline methods

As baseline methods, we

considered the Naïve and Naive Drift approaches. Both serve as reference points

for evaluating the performance of more complex forecasting models. These

methods provide simple and straightforward predictions that can be used to

benchmark the effectiveness of more sophisticated techniques.

The Naive method predicts

that the next value will be the same as the last observed value using the formula

described in eq. 3 It assumes that there is no change or trend in the data. The

equation uses the value for  using the previous value

using the previous value  of the time series.

of the time series.

(3)

(3)

Naive Drift, or the Drift

method, is a basic forecasting technique that assumes a linear trend in the

time series data. It is an extension of the Naive method, which predicts that

the next value will be the same as the last observed value. The Naive Drift

method, however, considers the time elapsed between observations and adjusts

the prediction based on this elapsed time, effectively incorporating a linear

trend or drift into the forecast.

2.2.2 Statistical methods

Statistical forecasting uses

historical data and statistical techniques to predict time series values and other

data types.

The ARIMA (Auto Regressive

Integrated Moving Average) method was developed and introduced in the early

1970s [13]. The fundamental concepts behind ARIMA were established by

the statisticians George E. P. Box and Gwilym M. Jenkins, and their work is

documented in the book titled ”Time Series Analysis: Forecasting and Control”,

which was first published in 1970. This method is still being used for time

series forecasting due to its good results, including forecasting using

industrial sensor data [14] [15] [16]. Another advantage of this method is that

it when only has limited historical data from the sensors to use during the

training phase [17].

2.2.3 Machine Learning

Machine learning can be

used for univariate time series forecasting by leveraging patterns and

relationships within historical data to predict future values of a single

variable over time.

Recurrent Neural Networks

(RNNs) are artificial neural network architecture that handle sequence data,

such as time series. Unlike traditional neural networks that process each input

individually, RNNs have feedback connections, allowing previous information to

influence the processing of subsequent inputs. The critical feature of RNNs is

their ability to maintain an internal memory or hidden state, which is updated

with each new input and influences future processing. This memory enables RNNs

to capture long-term dependencies in data sequences, making them particularly

useful in situations when the previous context is relevant for understanding

the current context.

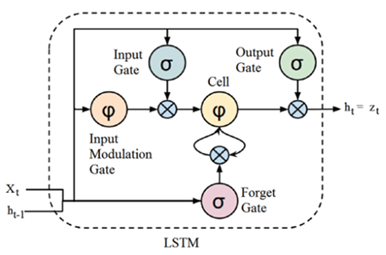

In the paper [18], Hochreiter and

Schmidhuber proposed the LSTM architecture to solve the vanishing gradient

problem that can occur in traditional recurrent neural networks (RNNs). The key

element that gives the capability to capture long-term dependencies to LSTM is

called memory block and described in Figure 4.

Figure 4 – LSTM diagram

Source: [19].

Due to this memory block, LSTMs

can handle long-range dependencies and capture patterns in sequences over

extended time intervals, making them highly suitable for tasks involving

sequential data, such as time-series forecasting [19] [20] [21] [22].

2.4 HYPERPARAMETERS SEARCH

Hyperparameter search is

the process of finding the best set of hyperparameters for a machine learning

model [23]. Hyperparameters are parameters that control the learning

process of the model but are not learned from the data. Some common examples of

hyperparameters include the learning rate, the number of epochs, and the number

of hidden layers in a neural network.

2.5 FORECASTING ACCURACY

Forecasting accuracy refers

to the degree of closeness between the predicted values from a forecasting

model and the real data of the target variable. It measures how well a

forecasting model can accurately capture the underlying patterns, trends, and

variations in the data to make accurate predictions of future values.

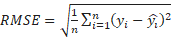

The forecast accuracy

measures are always calculated using test data that were not used when

computing the forecasts [24]. When using forecasts that are on the

same scale, the root mean square error (RMSE) is one of the recommended methods

and it is defined using the formula in (4). In the equation n is the

number of observations,  is the real observed value

at time, and

is the real observed value

at time, and  is the predicted value at

time

is the predicted value at

time  .

.

(4)

(4)

3 MATERIALS AND METHODS

This section provides a

comprehensive overview of the executed steps. It begins with data loading,

followed by preprocessing. Next, we delve into training using four distinct

methods. Finally, we present the results obtained from these methods.

3.1 DATA SET

The first step executed

during this study was to perform the data preprocessing required on the

collected data from the industrial sensors. The collected sensor data was saved

in a CSV file, including the timestamp and temperature attributes. The dataset

range starts from 00:00 of 1st of June of 2022, to 23:59 of June 29,

2022 with a total of 88,741 sensor readings. This represents an average of

3,060 readings per day.

The data from this CSV was

loaded as a time series and plotted using a Python data visualization library

called Matplotlib [26] to execute the first visual inspection and analysis. During

this first visual inspection of Figure 6, it was possible to see a similar

behavior of the time series along the collected period, indicating the time

series could be identified as stationary and requiring a stationarity test to

be executed [9].

3.2 PREPROCESSING

The subsequent step involved

identifying outliers using mean absolute deviation (MAD), eliminating them, and

then employing linear interpolation to fill the gaps left in the time series due

to these removals. This process detected and replaced 1,031 outliers in the

time series and can be visualized in Figure 7. The total length of the time

series was not affected because all removed outliers were replaced using linear

interpolation.

Another executed step was

to verify the time series stationarity to validate this hypothesis identified

in the visual inspection after plotting the time series. The Augmented

Dickey–Fuller (ADF) [9] test was executed and confirmed the collected sensor

data created a stationary time series. The ADF test returned a p-value equals

to 3.408511793361129e−29, and since this value is less than or equal to

0.05, H0 was rejected, and stationarity was confirmed.

The data set was then split

into training and test data sets. The division of 80/20 was used to split,

meaning the training data set was created with 80% of the values total and test

20%. Their sizes were 70,992 and 17,749 sensor readings. After this split, both

data sets were normalized as described in section 2.1 using the normalization

parameters obtained from the training data set. The result of this step can be

observed in Figure 8.

3.3 EXPERIMENTAL METHODOLOGY

The forecast range selected

in our experiments was from one step forward to ten steps. The forecasting used

walk-forward validation with a sliding window described in Figure 3. The

sliding window size was set according to the forecasting range for each

iteration of the test. This means the executed test was repeated 10 times with

different forecasting ranges, varying from 1 to 10.

The first baseline

forecasting method executed was the Naive forecast. The forecast horizon

selected for this method was from one step to ten steps forward. The forecast

was executed using the test data set for each different value of the forecast

horizon and always using the previous observed value to determine the

forecasted values. The accuracy of this method is presented in Table 1.

Table 1 – Naive Forecasting RMSE.

|

Forecast horizon

|

RMSE

|

|

1 step

|

0.020107

|

|

2 steps

|

0.028467

|

|

3 steps

|

0.035618

|

|

4 steps

|

0.040981

|

|

5 steps

|

0.047885

|

|

6 steps

|

0.053208

|

|

7 steps

|

0.054365

|

|

8 steps

|

0.059190

|

|

9 steps

|

0.064050

|

|

10 steps

|

0.069753

|

Source: Author.

The following executed

forecasting method was Naive Drift and the same forecasting horizons from the

previous method were also used in this one as well. For this method, different

subsets of the training data set were used to verify if smaller training

subsets can speed up the training phase without compromising the accuracy of

the forecasts. The training data sets were tested using the lengths described

in Table 2.

Table 2 – Training data set lengths

used for in models.

|

Training data set lengths

|

|

50

|

|

100

|

|

500

|

|

1000

|

|

10,000

|

|

20,000

|

|

50,000

|

|

70,000

|

Source: Author.

After some preliminary

experiments, the best accuracy with the lower RMSE was observed with 50,000

values from the training data set. Using the complete data set or more

significant amounts was unnecessary to achieve better accuracy for this

forecasting method. The result of this method was very similar when compared to

the previous method, Naive, even having much more data being used for the

training compared to Naive since it only uses the previous n readings. One of

the possible reasons for this is due to the high-frequency nature of the time

series used in this experiment, which helps in the first method. The RMSE for

this method is described in Table 3.

Table 3 – Naive Drift Forecasting lowest

RMSEs.

|

Forecast horizon

|

RMSE

|

|

1 step

|

0.020107

|

|

2 steps

|

0.028467

|

|

3 steps

|

0.035619

|

|

4 steps

|

0.040982

|

|

5 steps

|

0.047886

|

|

6 steps

|

0.053210

|

|

7 steps

|

0.054367

|

|

8 steps

|

0.059192

|

|

9 steps

|

0.064053

|

|

10 steps

|

0.069757

|

Source: Author.

Auto ARIMA was also

executed with the same data set and the same forecasting horizons as the

previous method. The length of the training data set was also tested using the

different values defined in Table 2, using the same approach as the Naive Drift

method that was previously executed. As was initially expected, this method

resulted in better accuracy than the baseline methods. Moreover, according to Table

7 some scenarios of multistep ahead required less training to obtain better

accuracy. The RMSE of this method is described in Table 4 and Table 7, the

latter includes the length of the training data set that resulted in the lowest

RMSE value. For this method, the StatsForecast [26] Python library was used.

Table 4 – Auto ARIMA Forecasting lowest

RMSEs.

|

Forecast Horizon

|

RMSE

|

|

1 step

|

0.018433

|

|

2 steps

|

0.026235

|

|

3 steps

|

0.033717

|

|

4 steps

|

0.039248

|

|

5 steps

|

0.043817

|

|

6 steps

|

0.051401

|

|

7 steps

|

0.052531

|

|

8 steps

|

0.055412

|

|

9 steps

|

0.064519

|

|

10 steps

|

0.066474

|

Source: Author.

After completing the tests

with the baselines and statistical methods, the same data set was executed

using a Long Short-Term Memory (LSTM) recurrent neural network [18]. This model was selected because

of its ability to capture long-range dependencies [18] and due to this it can effectively

handle sequential data such as time-series, which is the case in the dataset

being used in this study.

The first executed step was

the hyperparameters tuning. This was done using an open-source Python package

for hyperparameter optimization framework named Optuna [23] that allows to dynamically define

the hyperparameters search space to find its optimal values. The hyperparameters

search was executed using the following ranges.

·

Number

of layers: 1 - 100

·

Size of

hidden layer: 1 - 250

·

Dropout:

0.0 – 0.9

·

Epochs:

1 - 999

As a result of this search,

the following values were found and used in the LSTM model:

·

Number

of layers: 1

·

Size of

hidden layer: 11

·

Dropout:

0.12491736459588197

·

Epochs:

405

·

Learning

Rate: 1e-3

·

Optimizer

Class: Adam

The RMSE obtained by this

method can be visualized in Table 5.

Table 5 – LSTM Forecasting lowest RMSEs.

|

Forecasting Horizon

|

RMSE

|

|

1 step

|

0.016199

|

|

2 steps

|

0.020448

|

|

3 steps

|

0.025473

|

|

4 steps

|

0.028625

|

|

5 steps

|

0.031311

|

|

6 steps

|

0.035913

|

|

7 steps

|

0.036612

|

|

8 steps

|

0.038325

|

|

9 steps

|

0.044608

|

|

10 steps

|

0.044678

|

Source: Author.

4 RESULTS COMPARISON

The first step was to

verify with the Friedman test [28] if there is significant statistical

difference observed across the collected values or if they could have occurred

by chance. The test returned p-value rejecting the null hypothesis of the test,

meaning there are significant differences among the obtained RMSEs from each

method.

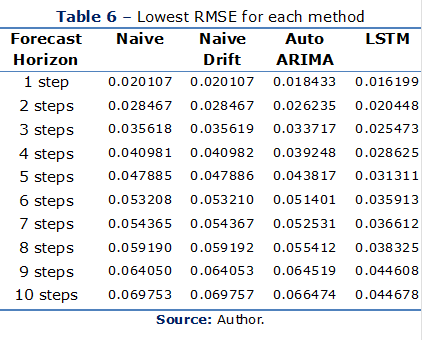

Then, a comparison between

the selected methods using the lowest RMSE values collected for each forecast

horizon regardless of the length of the training data set, which means that the

optimal size of the training data set was used in this first comparison. As presented

in Table 6, LSTM outperformed the other methods in all different forecasting

horizon scenarios. Auto ARIMA was the second on the list followed by Naive

Drift and Naïve, which obtained similar values for the RMSE. LSTM outperformed

Auto ARIMA by an average of 4.83%. Auto ARIMA outperformed Naive Drift and

Naive by an average of 21.30%.

Figure 9 and 10 shows the

comparison among all selected methods to their forecasting time. The first

image presents the amount of time that each method took to execute the

forecasting for all horizons. The second image presents the average time for

each forecasting step, also in horizons.

It was

also observed in Figure 11 that LSTM underperforms statistical methods when

using small training data sets. The same figure shows that the LSTM outperforms

the other selected methods only when the training data set contains at least

500 sensor readings.

5 CONCLUSIONS

In this work, we present different

forecasting techniques used to build a real-world Industry 4.0 application

using concepts of Digital Twins. This experiment used real data collected from

a temperature sensor during the initial stages of a manufacturing process were

used.

The provided results

contain information to conclude that LSTM obtained a better outcome for the

RMSE when using large training data sets. LSTM got similar or lower results

when working with a small training data set. This means that LSTM must be carefully

selected depending on the amount of data available to train the model.

Moreover, Figure 9 and 10 shows LSTM taking more processing time than the other

selected methods in the forecasting phase. It also adds an extra step in the

process: which is the hyperparameters search before fitting the model.

It is also clear that,

despite the discussed drawbacks of using LSTM models, its accuracy gains can

have a significant positive impact, especially in the context of Digital Twins

and industrial applications [29]. The following points can be

observed:

·

Accuracy

Gains:

LSTM models are known for capturing sequential patterns and dependencies in

data, making them valuable for time series forecasting and predictive modeling.

Given that it resulted in improved accuracy, it can lead to more reliable

predictions and decision-making. According to

the results presented in

this work, LSTM outperformed Auto ARIMA by an average of 4.83%, which be enough

to avoid equipment faults and reduced maintenance tasks.

·

Reduced

Resource Usage: By achieving more accurate predictions, the usage of industrial, such

as natural gas and electricity, can be optimized. This means that utility resources

can be used more efficiently, potentially reducing costs, minimizing waste, and

reducing the environmental impact.

·

Financial

Impact:

Even small gains in RMSE can translate to significant cost savings in an

industrial environment. This is particularly crucial in industries where energy

consumption, resource utilization, and operational efficiency are closely

monitored and directly impact on the bottom line.

In summary, despite the potential drawbacks of using

LSTM models, their ability to enhance accuracy and, consequently, reduce

resource consumption and costs can make them a valuable tool in the context of

Digital Twins and industrial operations. However, it's important to continue

refining and fine-tuning these models to mitigate their limitations and

maximize their benefits.

The following

topics can be used for future work around the subject of this paper.

·

How to

identify the most optimal length of the training data set without having to

test different lengths?

·

Execute

comparisons using different multi-step ahead forecast strategies, such as recursive,

direct and hybrid.

·

Execute

forecasting using multivariate timeseries by using information from other

digital twin’s sensor data and its geolocations. With the objective to predict

failures and reduce utility consumption.

REFERENCES

[1] GRIEVES,

Michael; VICKERS, John. Origins of the digital twin concept. Florida

Institute of Technology, v. 8, p. 3-20, 2016.

[2] ATTARAN, Mohsen; CELIK,

Bilge Gokhan. Digital Twin: Benefits, use cases, challenges, and

opportunities. Decision Analytics Journal, p. 100165, 2023.

[3] OLCOTT, S.; MULLEN, C.

Digital twin consortium defines digital twin. Available at: blog.digitaltwinconsortium.org/2020/12/

digital-twin-consortium-defines-digital-twin.html, 2020.

[4] BLÁZQUEZ-GARCÍA, Ane et al. A review on outlier/anomaly detection in

time series data. ACM Computing Surveys (CSUR), v. 54, n. 3, p.

1-33, 2021.

[5] KHAYATI,

Mourad et al. Mind the gap: an experimental evaluation of imputation of missing

values techniques in time series. In: Proceedings of the VLDB Endowment.

2020. p. 768-782.

[6] LIMA, Felipe Tomazelli; SOUZA, Vinicius

MA. A Large Comparison of Normalization Methods on Time Series. Big

Data Research, v. 34, p. 100407, 2023.

[7] LEYS, Christophe et al.

Detecting outliers: Do not use standard deviation around the mean, use absolute

deviation around the median. Journal of experimental social psychology,

v. 49, n. 4, p. 764-766, 2013.

[8] TROYANSKAYA, Olga et al.

Missing value estimation methods for DNA microarrays. Bioinformatics,

v. 17, n. 6, p. 520-525, 2001.

[9] MUSHTAQ,

Rizwan. Augmented dickey fuller test. 2011.

[10] FULLER, Wayne A. Introduction

to statistical time series. John Wiley & Sons, 2009.

[11] VAFAEIPOUR,

Majid et al. Application of sliding window technique for prediction of wind

velocity time series. International Journal of Energy and Environmental

Engineering, v. 5, p. 1-7, 2014.

[12] BERGMEIR, Christoph; BENÍTEZ, José M. On

the use of cross-validation for time series predictor evaluation. Information

Sciences, v. 191, p. 192-213, 2012.

[13] BOX, G.E.P.; JENKINS, G. M.;

REINSEL, G. C. Time series analysis: forecasting and control. John

Wiley & Sons, 2011.

[14] KANAWADAY, A.;

SANE, A. Machine learning for predictive maintenance of industrial machines

using IoT sensor data. In: 2017 8th IEEE international conference on

software engineering and service science (ICSESS). IEEE, 2017. p. 87-90.

[15] ZHANG,

Weishan et al. LSTM-based analysis of industrial IoT equipment. IEEE

Access, v. 6, p. 23551-23560, 2018.

[16] MANI, Geetha;

VOLETY, Rohit. A comparative analysis of LSTM and ARIMA for enhanced real-time

air pollutant levels forecasting using sensor fusion with ground station

data. Cogent Engineering, v. 8, n. 1, p. 1936886, 2021.

[17] ELSARAITI,

Meftah; MERABET, Adel; AL-DURRA, Ahmed. Time Series Analysis and Forecasting of

Wind Speed Data. In: 2019 IEEE Industry Applications Society Annual

Meeting. IEEE, 2019. p. 1-5.

[18] HOCHREITER,

Sepp; SCHMIDHUBER, Jürgen. Long short-term memory. Neural computation,

v. 9, n. 8, p. 1735-1780, 1997.

[19] CHHAJER,

Parshv; SHAH, Manan; KSHIRSAGAR, Ameya. The applications of artificial neural

networks, support vector machines, and long–short term memory for stock market

prediction. Decision Analytics Journal, v. 2, p. 100015, 2022.

[20] TAN, Mao et al.

Ultra-short-term industrial power demand forecasting using LSTM based hybrid

ensemble learning. IEEE transactions on power systems, v. 35, n. 4,

p. 2937-2948, 2019.

[21] ZHANG, Weishan et al. LSTM-based analysis of

industrial IoT equipment. IEEE Access, v. 6, p. 23551-23560, 2018.

[22] COOK, Andrew

A.; MISIRLI, Göksel; FAN, Zhong. Anomaly detection for IoT time-series data: A

survey. IEEE Internet of Things Journal, v. 7, n. 7, p. 6481-6494,

2019.

[23]

AKIBA, Takuya et al. Optuna: A next-generation hyperparameter

optimization framework. In: Proceedings of the 25th ACM SIGKDD

international conference on knowledge discovery & data mining. 2019. p.

2623-2631.

[24]

HYNDMAN, Rob J. Measuring forecast accuracy. Business

forecasting: Practical problems and solutions, p. 177-183, 2014.

[25] HYNDMAN, Rob J.; KOEHLER, Anne B. Another look at

measures of forecast accuracy. International journal of forecasting, v. 22,

n. 4, p. 679-688, 2006.

[26] HUNTER, John

D. Matplotlib: A 2D graphics environment. Computing in science &

engineering, v. 9, n. 03, p. 90-95, 2007.

[27] GARZA,

Federico et al. StatsForecast: Lightning fast forecasting with statistical and

econometric models. PyCon: Salt Lake City, UT, USA, 2022.

[28] FRIEDMAN,

Milton. A comparison of alternative tests of significance for the problem of m

rankings. The annals of mathematical statistics, v. 11, n. 1, p.

86-92, 1940.

[29] CHOI,

Eunjeong; CHO, Soohwan; KIM, Dong Keun. Power demand forecasting using long

short-term memory (LSTM) deep-learning model for monitoring energy sustainability. Sustainability,

v. 12, n. 3, p. 1109, 2020.